Contract Research and Development (R&D)

In an industry that is changing fast, firms must continually revise their design and range of products. This is necessary due to continuous technology change and development as well as other competitors and the changing preference of customers. Without an R&D program, a firm must rely on strategic alliances, acquisitions, and networks to tap into the innovations of others.

Selnolab Sdn. Bhd. provides a variety of services for organizations seeking support for research, performance and development projects. With a state-of-the-art instrumentation and a skilled team of analysts, Selnolab develops analytical methods for projects executed at its premises as well as for external inquiries at any stage of a project. Our solid R&D team of trained academicians and researchers with industrial backgrounds enables us to cater to the following clusters.

Nanomaterials and Chemical Products

Selnolab provides a one-stop, continuous range of problem-solving expertise in nanomaterials which includes catalysts, adsorbent, zeolite and activated carbon, supported by world-class analytical services. Selnolab is able to assist leading industrialists in designing and formulating their own chemicals according to its specific function which also includes medical devices, drug deliveries and cosmetics. Whether it’s developing a new process or improving an existing synthetic route, Selnolab can make an impact in the following areas:

- reducing the number of synthetic steps and costs;

- increasing process efficiency, yield and throughput;

- replacing dangerous or environmentally unsuitable chemistries;

- working with complex molecules and multi-step syntheses;

- developing and optimizing existing processes to produce syntheses amenable to commercial manufacturing

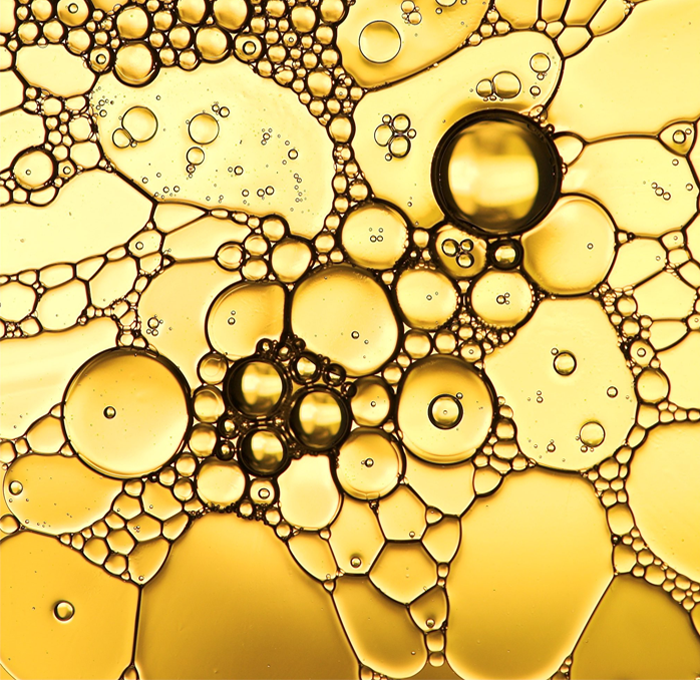

Energy and Renewable Energy

Selnolab have extensive experience in energy and renewable energy processes and have created a number of processes running today at industrial scale. Clients seeking to improve troublesome steps in a process, or to redesign an entire energy route for one of their potential APIs or key intermediates, will value the team at Selnolab. Our goal is to develop for our clients scalable processes that are safe, environmentally sound, robust and cost effective. These includes materials modification of solar panels, waste to energy processes, production of biofuels and re-engineering the properties of fuels and industrial lubricants.